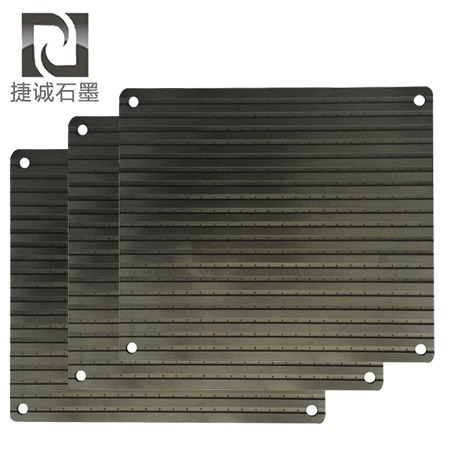

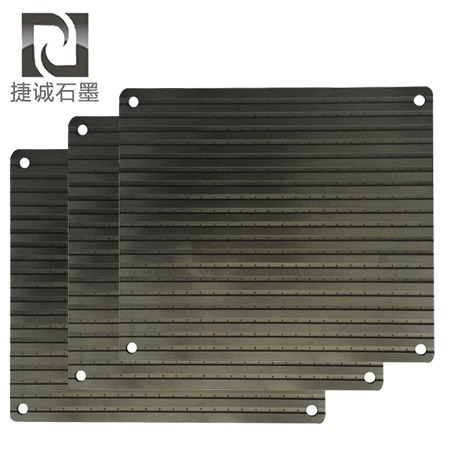

High temperature resistant hot pressing ink burning die:

1. The sintered graphite mold requires high purity, the content of fixed carbon is greater than 85%, and the content of harmful impurities is less than 1%. In recent years, high-speed milling has broken through the difficulty of traditional milling to process high hardness

2. Limitations of high strength and high toughness die materials. However, EDM has high machining accuracy and surface quality and wide machining range, especially in complex, precision, thin wall, narrow gap

3. The advantages of die cavity machining of high hard materials can not be compared with high-speed milling, so EDM will still be the main method of die cavity machining.

4. Compared with copper, graphite electrode has the advantages of less electrode consumption, fast EDM speed, good machining performance, light weight and low coefficient of thermal expansion,

5. Gradually replace copper electrode and become the mainstream of EDM electrode. Compared with copper, graphite electrode has the advantages of less consumption, fast discharge speed

6. It has the advantages of light weight and low coefficient of thermal expansion, so it gradually replaces copper electrode and becomes the mainstream of EDM electrode.