product_detail

Vacuum furnace graphite parts manufacturer - Shenyang vacuum furnace graphite parts - Huarui vacuum - Huahong vacuum furnace - Dongguan Jiecheng graphite products Co., Ltd. - technological innovation

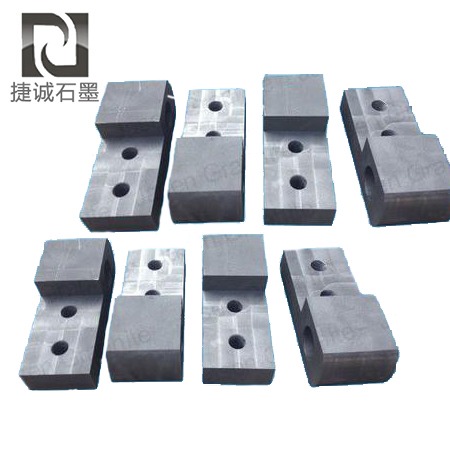

There are various kinds of graphite products, which are often seen in our life. But in the current situation, what kind of development prospects will graphite products manufacturers have? What problems will it face? In the modern society, graphite products industry plays a key role in our life. The development of vacuum furnace graphite parts manufacturers and many industrial sectors depend on the technical improvement and development of mold industry. At present, the market competition of graphite products is quite fierce, many enterprises are facing huge survival pressure and development adversity, and few enterprises can be smooth sailing in the process of development. I believe we all know such a phenomenon: there are many fake products in the graphite products market, and the homogenization is also serious. Many products are imitated, and many graphite products manufacturers lack the ability of development in the production process, so they can imitate the products produced by other manufacturers.

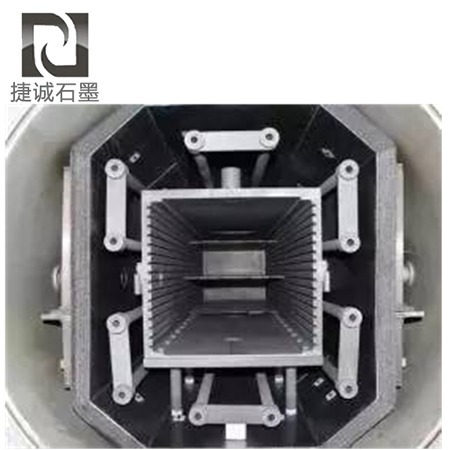

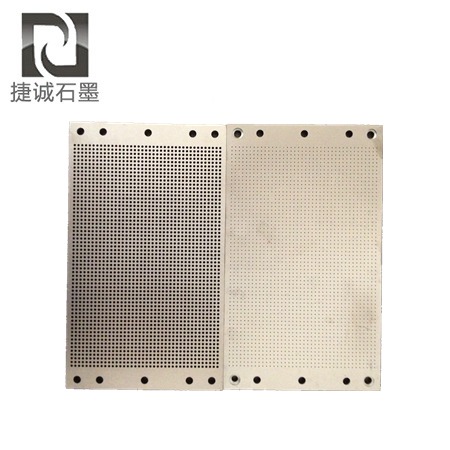

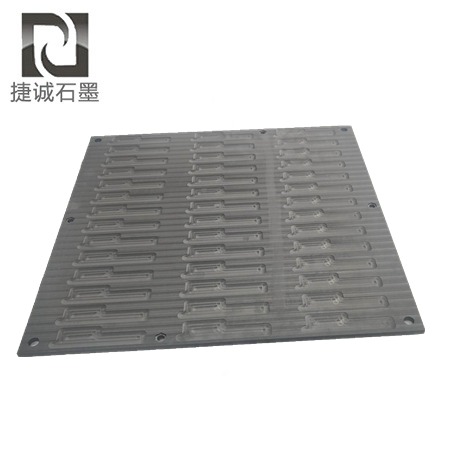

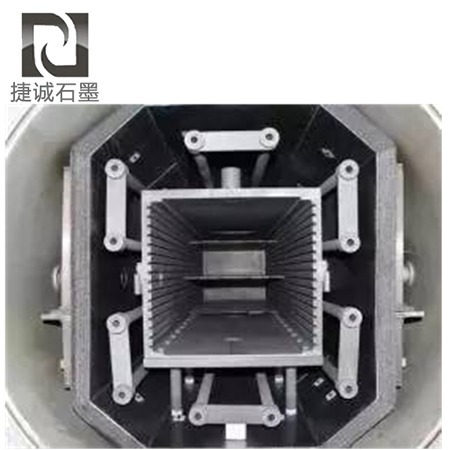

Graphite and other impurity materials can be used as carburizers in steelmaking industry. Carburizing uses a wide range of carbon materials, including artificial graphite, petroleum coke, metallurgical coke and natural graphite. In the world, graphite used as carburizing agent is still one of the main uses of earthy graphite. Graphite is widely used in the electrical industry as electrode, brush, carbon rod, carbon tube, graphite gasket, telephone parts, TV picture tube coating and so on. Among them, graphite electrode is widely used. When smelting all kinds of alloy steel and ferroalloy, graphite parts manufacturers of vacuum furnace use graphite electrode. At this time, the strong current is introduced into the smelting area of electric furnace through the electrode, which generates electric arc and converts electric energy into heat energy. The temperature rises to about 2000 degrees, so as to achieve the purpose of smelting or reaction. In addition, graphite electrode is also used as anode in electrolyzing magnesium, aluminum and sodium. Graphite electrode is also used as conductive material in resistance furnace for emery production.

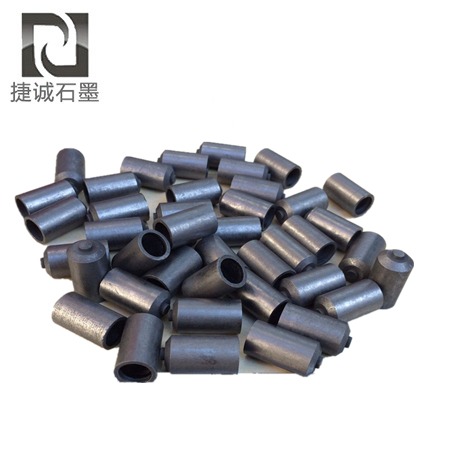

The high purity graphite crucible is easy to be affected by moisture. The product will soften after being affected by moisture, and some impact materials will deform after being hit. Once water enters the high purity graphite crucible, it will affect the raw materials in it. The quotation of graphite parts in vacuum furnace will cause dilution of raw materials, There will also be some chemical reactions to further affect its quality problems, so waterproof measures must be done well. Although the quality of high-purity graphite crucible is very good, and it is not easy to damage, it should be handled with care. Falling from high altitude or bumping has little effect on the quality of graphite crucible. The graphite parts of Shenyang vacuum furnace will crack if it goes on like this for a long time. There is no way to remedy this situation, so it can only be replaced.

Quotation of graphite parts for vacuum furnace - Xingde graphite - technological innovation - graphite parts for Shenyang vacuum furnace are provided by Liaoyang Xingde graphite Co., Ltd. Liaoyang Xingde graphite Co., Ltd. (www.lyxdsm. CN) has devoted a lot of enthusiasm and enthusiasm in the field of graphite and carbon products. Xingde graphite has been taking customers as the center, creating value for customers, and winning the market with quality and service. We sincerely hope to cooperate with all sectors of society to create success and brilliance.